Panko – Ohmic Cooking

- The Device: It was an insulated wooden box equipped with electrode plates.

- The Process: This utilized ohmic heating, where an electric current passes directly through the dough. The resistance of the dough generates heat internally, “baking” it from the inside out.

- The Result: Because there is no external heat source (like a hot oven wall), the bread never develops a brown, hard crust. This creates the signature large, jagged, and airy flakes that define authentic panko today.

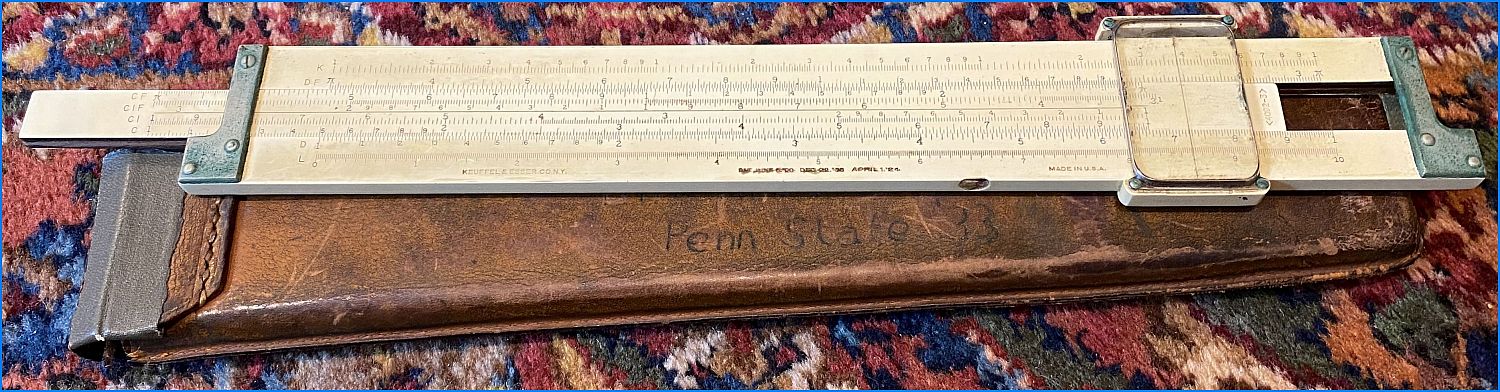

Slide Rules in Heat Transfer

Before electronic calculators became available in the early 1970’s, the slide rule was a heat transfer engineer’s best friend. It’s easy to imagine adding a length proportional to the logarithm of one number to a length proportional to the logarithm to get a length proportional to their product. But real men and women engineers went far beyond simple multiplication and division. They often needed a Reynolds or Prandtl number to some non-integral power (as in most convection correlations). This was a challenge requiring a log-log slide rule.

In the 1960s, just before electronic calculators made them obsolete, a high-quality slide rule cost the equivalent of about US$ 300 in today’s dollars. My high school even had a slide rule club for those aspiring to a STEM career.

Clearing Snow

My concrete driveway gets no direct sunlight until late afternoon. Clearing it after about 8″ of snow covered by 2″ of sleet has proven challenging.

As we know, the thermal conductivity of a layer of snow is much closer to that of air trapped within than to that of the water from which it is made:

Ambient air temperature has been around freezing and wind speeds light, so convection from the surface is minimal. At this latitude the temperature a few feet down is constant at about 55°F.